www.buildingsandcities.org/insights/commentaries/embodied-carbon.html

Embodied Carbon: Breaking Construction Dependencies

Viable alternatives exist to reduce the use of concrete in construction.

Does concrete have to be used widely? Given the large amounts of GHGs generated by concrete, what alternative materials and design optimisations exist? Ronita Bardhan (University of Cambridge) and Ramit Debnath (University of Cambridge) discuss some options for how we can immediately reduce concrete consumption.

The global building sector accounted for nearly 37% of the global carbon dioxide (CO2) emissions in 2020: building operations are responsible for 27% annually and building materials / construction processes (typically referred to as embodied carbon) are responsible for an additional 10% annually (UNEP 2021). Concrete is a primary contributor of embodied carbon emissions, accounting for 8% of global CO2 emissions. According to Intergovernmental Panel on Climate Change (IPCC), the global warming must be restricted to 1.5 °C by radically reducing GHG emissions. This means the CO2 emissions has to peak within a short time-window i.e., before 2030 and fall to net zero by around 2050. Thus, the urgent need to include embodied emissions (Fankhauser et al. 2022).

The challenges to reaching net-zero and resilient buildings and the construction sector are considerable, especially as 82% of the predicted population growth added by 2030 is in countries without any specific building emission reduction targets (UNEP 2021). In addition to radically reducing emissions from building operation, emissions from materials and construction processes must be urgently addressed to ensure that today's buildings are optimised for low-carbon solutions across the entire life cycle.

Comprehensive and sustainable solutions are needed. Replacing concrete from the construction and building sector requires a system-wide strategy. This involves evaluating each design choice using a whole lifecycle approach and seeking to minimise upfront carbon impacts (e.g. lean construction, low-carbon materials and construction processes, etc.), maximising the refurbishment of existing buildings and taking steps to avoid future embodied carbon during and at the end of life (Lützkendorf & Frischknecht 2020).

Materials to minimise upfront carbon impact

Bamboo is a versatile building material that is also rapidly renewable. Bamboo can be used in both pole construction (as scaffolding, roofing, framing elements, etc) and manufactured products (as engineered structural components, finishes, and acoustic and structural panels). Bamboo offers superior mechanical properties, tensile strength, elasticity, and cost-effectiveness as a building material. It has greater compressive strength than concrete and almost the same strength-to-weight ratio as steel in tension (Li et al. 2020) and a higher tensile strength than steel (Kathiravan et al. 2021), making it a low-carbon alternative to steel bars or structural steel members. Engineered bamboo structural components such as bamboo nail laminated timber systems have high elasticity, making them suitable for use in extreme wind and earthquake conditions. Bamboo is also fire resistant due to its high silica content.

Bamboo forests sequester carbon like timber forests; however, carbon sequestration varies significantly across 1600 bamboo species. The species predominantly used in building materials is the Moso bamboo that can sequester about 102-289 t/C per hectare annually in the forest ecosystem where it is grown. A unique characteristic of bamboo plants is that it does not die after harvesting, thereby avoiding any deforestation. For enabling bamboo as a carbon smart material in the current construction and building sector, policy support is needed to establish a robust supply chain of only specific bamboo species (e.g. Moso) in sustainably managed bamboo forests. Policy and strategy can ensure specification of bamboo products that come from sustainability managed forests and not created through land-use change like clearing natural timber forests for bamboo plantations (Xu et al. 2018). Moreover, sourcing bamboo products locally can reduce transportation emissions and specification can also avoid fossil fuel emissions during the manufacture of engineered bamboo components.

Hempcrete is another low-carbon material for building structural applications. It is a monolithic wall system that consists of hemp hurd (the inner woody core of the hemp plant, also called shiv), lime, and a hydraulic additive over structural support. Industrial hemp absorbs 8 - 15 t/CO2 per hectare of cultivation, capturing atmospheric carbon twice as effectively as forests while providing carbon-negative biomaterials for the built environment (Ahmed et al. 2022). Hemp demands little water to grow and therefore can have high drought resilience. It grows approximately 50 times faster than a tree, allowing it to be rapidly cultivated for industrial applications.

Hempcrete wall systems have high thermal performance owing to their high thermal mass and insulation property (R-value: 0.67/cm to 1.2/cm). It transmits humidity, is fireproof, deters insects and rodents, resists mould and has excellent acoustic performance. It is also recyclable, does not emit volatile organic compounds (VOC) or other toxins, and can endure for centuries.

Timber from managed forestry also stores carbon instead of emitting it. As a rule of thumb, a cubic metre of wood contains around a tonne of CO2 (depending on the tree species). When used as structural timber (also known as mass timber), the wood provides promise for a low carbon built environment at scale (Churkina et al. 2020). Mass timber is a generic term that encompasses products of various sizes and functions, like glued-laminated (glulam) beams, laminated veneer lumber (LVL), nail-laminated timber (NLT), dowel-laminated timber (DLT) and cross-laminated timber (CLT). Apart from emission reduction in the building and construction sector, mass timber buildings offer additional benefits: better fire performance, faster construction with less waste and better earthquake performance compared with concrete structures. Additionally, it is aesthetically pleasing and can generate rural livelihood.

Concrete 2.0: less than 'concrete'

Around 79% of concrete's CO2 emissions come from the cement even though it only represents 13% of the material. It is estimated that around 1 tonne of CO2 is emitted in producing per ton of clinker. The International Energy Agency (IEA 2021) estimates that the ways to reduce these emissions are (i) improving the energy efficiency of the cement production processes by using alternative fuels and/or biomass, (ii) promoting material efficiency by reducing the clinker-to-cement ratio, and (iii) by advancing process and technology innovations for replacing cement with complementary cementing materials (CCM) and lastly iv) carbon capture and storage. This new generation of concrete produced is often termed Concrete 2.0 or 'green' cement, a more sustainable alternative to the traditional one. However, greening the cement industry will need significant effort and investment to implement this. A critical factor is the replacement costs of traditional cement production facilities particularly issues surrounding their sunk costs. Current knowledge remains blurred on where and how the Cement 2.0 is resourced, produced and distributed. There is also lack of information on the net-zero fuel mix required to completely decarbonise the cement industry.

The promise of Concrete 2.0 is to reduce the carbon content: alternatives to Portland cement are based on different chemical compositions (e.g. alternatives to clinker: pozzolans, the Third Cement Series or recycled concrete) but there are consequences for structural performance and cost. Approximately 26% of Britain's concrete is already manufactured using recycled concrete.

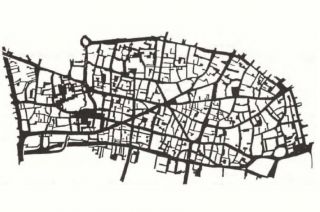

However, the real challenge is in the developing world, which is yet to build two-thirds of its required building stock. The carbon emissions from the cement industry have increased by 186% between 1990 and 2019. The majority of this growth is witnessed in developing countries in Asia, the Middle East and Africa, where new infrastructure is being built (Chen, et al. 2020). The study suggested an annual growth rate between 20-40% in China, India and sub-Saharan Africa.

Material replacement and design optimisation

Design optimisation of concrete elements can reduce the amount of concrete used and the resulting embodied emissions. Optimally shaped horizontal spanning elements, such as floor beams and slabs, can reduce 80% of the structural mass and massive trapped embodied energy without compromising the strength (Ismail et al. 2021). The trade-offs between operational and embodied carbon need to be considered together over the life cycle. In some situations, it may be advisable to use a material with high embodied carbon if it reduces operational carbon emissions and results in substantially lower overall emissions. This calculation is far from easy, as it also introduces the question of time - when it is most advantageous to reduce emissions. Suitable policy frameworks that can provide clarity to designers, specifiers and manufacturers would provide more confidence in innovative materials and technology and help to decarbonise future growth.

Conclusions

A rapid transition is needed to reduce GHG emissions from the building stock: both embodied and operational emissions. Viable alternatives to concrete exist that can used today in many situations by engineers, specifiers and contractors. Solutions require a holistic understanding of the impacts of specified materials.

Governments must broaden their regulations to include embodied GHGs within the regulatory framework for buildings. A life-cycle analysis approach is recommended that combines operational and embodied GHGs.

Construction professionals have a duty of care to use and promote materials with low embodied carbon. The research community can assist with this by providing solutions involving alternative materials. In-depth research is needed to catalogue the benefits and co-benefits of alternative materials and provide clear methods for carbon accounting (Hoxha et al. 2020). A systems approach is needed to understand the impacts of concrete and the choice for alternative material while equalising the distributive impacts.

References

Ahmed, A. T. M. F., Islam, M. Z., Mahmud, M. S., Sarker, M. E. & Islam, M. R. (2022). Hemp as a potential raw material toward a sustainable world: A review. Heliyon, 8, e08753.

Chen, C., Xu, R., Tong, D., Qin, X., Cheng, J., Liu J., Zheng, B., Yan, L. & Zhang, Q. (2022). A striking growth of CO2 emissions from the global cement industry driven by new facilities in emerging countries. Environmental Research Letters, 17, 044007 (2022).

Churkina, G., Organschi, A., Reyer, C.P.O., Ruff, A., Vinke, K., Liu, Z., Reck, B.K., Graedel, T.E. & Schellnhuber, H.J. (2020). Buildings as a global carbon sink. Nature. Sustainability, 3, 269-276.

Fankhauser, S., Smith, S.M., Allen, M. et al. (2022). The meaning of net zero and how to get it right. Nature Climate Change, 12, 15-21. https://doi.org/10.1038/s41558-021-01245-w

Lützkendorf, T., & Frischknecht, R. (2020). (Net-) zero-emission buildings: a typology of terms and definitions. Buildings and Cities, 1, 662-675. DOI: http://doi.org/10.5334/bc.66

Hoxha, E., Passer, A., Saade, M. R. M., Trigaux, D., Shuttleworth, A., Pittau, F., Allacker, K. & Habert, G. (2020). Biogenic carbon in buildings: a critical overview of LCA methods. Buildings and Cities, 1, 504-524. DOI: http://doi.org/10.5334/bc.46

IEA. (2021). Cement. International Energy Agency. https://www.iea.org/reports/cement

Ismail, M. A., Mayencourt, P. L. & Mueller, C. T. (2021). Shaped beams: unlocking new geometry for efficient structures. Architecture, Structures and Construction, 1, 37-52.

Kathiravan, N. S., Manojkumar, R., Jayakumar, P., Kumaraguru, J. & Jayanthi, V. (2021). State of art of review on bamboo reinforced concrete. Materials Today Proceedings, 45, 1063-1066.

Li, Z., Chen, C., Mi, R., Gan, W. Dai, J., Jiao, M., Xie, H. Yao, Y. Xiao, S. & Hu, L. (2020). A strong, tough, and scalable structural material from fast‐growing bamboo. Advanced Materials, 32, 1906308.

UKGBC. (2019). Net zero carbon buildings: a framework definition. London: UK Green Building Council.

UNEP. (2021). Global status report for buildings and construction: towards a zero‑emission, efficient and resilient buildings and construction sector. Nairobi: United Nations Environment Programme.

Xu, M., Ji, H. & Zhuang, S. (2018). Carbon stock of Moso bamboo (Phyllostachys pubescens) forests along a latitude gradient in the subtropical region of China. PLOS ONE 13(2): e0193024.

Latest Peer-Reviewed Journal Content

Energy sufficiency, space temperature and public policy

J Morley

Living labs: a systematic review of success parameters and outcomes

J M Müller

Towards a universal framework for heat pump monitoring at scale

J Crawley, L Domoney, A O’Donovan, J Wingfield, C Dinu, O Kinnane, P O’Sullivan

Living knowledge labs: creating community and inclusive nature-based solutions

J L Fernández-Pacheco Sáez, I Rasskin-Gutman, N Martín-Bermúdez, A Pérez-Del-Campo

A living lab approach to co-designing climate adaptation strategies

M K Barati & S Bankaru-Swamy

Mediation roles and ecologies within resilience-focused urban living labs

N Antaki, D Petrescu, M Schalk, E Brandao, D Calciu & V Marin

Negotiating expertise in Nepal’s post-earthquake disaster reconstruction

K Rankin, M Suji, B Pandey, J Baniya, D V Hirslund, B Limbu, N Rawal & S Shneiderman

Designing for pro-environmental behaviour change: the aspiration–reality gap

J Simpson & J Uttley

Lifetimes of demolished buildings in US and European cities

J Berglund-Brown, I Dobie, J Hewitt, C De Wolf & J Ochsendorf

Expanding the framework of urban living labs using grassroots methods

T Ahmed, I Delsante & L Migliavacca

Youth engagement in urban living labs: tools, methods and pedagogies

N Charalambous, C Panayi, C Mady, T Augustinčić & D Berc

Co-creating urban transformation: a stakeholder analysis for Germany’s heat transition

P Heger, C Bieber, M Hendawy & A Shooshtari

Placemaking living lab: creating resilient social and spatial infrastructures

M Dodd, N Madabhushi & R Lees

Church pipe organs: historical tuning records as indoor environmental evidence

B Bingley, A Knight & Y Xing

A framework for 1.5°C-aligned GHG budgets in architecture

G Betti, I Spaar, D Bachmann, A Jerosch-Herold, E Kühner, R Yang, K Avhad & S Sinning

Net zero retrofit of the building stock [editorial]

D Godoy-Shimizu & P Steadman

Co-learning in living labs: nurturing civic agency and resilience

A Belfield

The importance of multi-roles and code-switching in living labs

H Noller & A Tarik

Researchers’ shifting roles in living labs for knowledge co-production

C-C Dobre & G Faldi

Increasing civic resilience in urban living labs: city authorities’ roles

E Alatalo, M Laine & M Kyrönviita

Co-curation as civic practice in community engagement

Z Li, M Sunikka-Blank, R Purohit & F Samuel

Preserving buildings: emission reductions from circular economy strategies in Austria

N Alaux, V Kulmer, J Vogel & A Passer

Urban living labs: relationality between institutions and local circularity

P Palo, M Adelfio, J Lundin & E Brandão

Living labs: epistemic modelling, temporariness and land value

J Clossick, T Khonsari & U Steven

Co-creating interventions to prevent mosquito-borne disease transmission in hospitals

O Sloan Wood, E Lupenza, D M Agnello, J B Knudsen, M Msellem, K L Schiøler & F Saleh

Circularity at the neighbourhood scale: co-creative living lab lessons

J Honsa, A Versele, T Van de Kerckhove & C Piccardo

Positive energy districts and energy communities: how living labs create value

E Malakhatka, O Shafqat, A Sandoff & L Thuvander

Built environment governance and professionalism: the end of laissez-faire (again)

S Foxell

Co-creating justice in housing energy transitions through energy living labs

D Ricci, C Leiwakabessy, S van Wieringen, P de Koning & T Konstantinou

HVAC characterisation of existing Canadian buildings for decarbonisation retrofit identification

J Adebisi & J J McArthur

Simulation and the building performance gap [editorial]

M Donn

Developing criteria for effective building-sector commitments in nationally determined contributions

P Graham, K McFarlane & M Taheri

Join Our Community

The most important part of any journal is our people – readers, authors, reviewers, editorial board members and editors. You are cordially invited to join our community by joining our mailing list. We send out occasional emails about the journal – calls for papers, special issues, events and more.

We will not share your email with third parties. Read more

Latest Commentaries

COP30 Report

Matti Kuittinen (Aalto University) reflects on his experience of attending the 2025 UN Conference of the Parties in Belém, Brazil. The roadmaps and commitments failed to deliver the objectives of the 2025 Paris Agreement. However, 2 countries - Japan and Senegal - announced they are creating roadmaps to decarbonise their buildings. An international group of government ministers put housing on the agenda - specifying the need for reduced carbon and energy use along with affordability, quality and climate resilience.

Building-Related Research: New Context, New Challenges

Raymond J. Cole (University of British Columbia) reflects on the key challenges raised in the 34 commissioned essays for Buildings & Cities 5th anniversary. Not only are key research issues identified, but the consequences of changing contexts for conducting research and tailoring its influence on society are highlighted as key areas of action.